Controlled airflow and delamination are important aspects in the manufacturing process of

embossed non-woven fabric, influencing its texture, thickness, and overall properties. Here's a closer look at the roles of controlled airflow and delamination:

Controlled Airflow:

Fiber Dispersion:

Uniform Distribution: Controlled airflow is often used in processes like airlaid and carding to ensure the uniform dispersion of fibers. This helps create an even web of fibers before further processing.

Layer Formation:

Layering: In the airlaid process, where fibers are dispersed using air, controlled airflow assists in forming layers of fibers. The controlled movement of fibers allows for the creation of a uniform and well-layered web.

Orientation Control:

Fiber Orientation: The direction and strength of the airflow can influence the orientation of fibers in the web. Adjustments in airflow parameters can be used to control the alignment of fibers, affecting the overall strength and characteristics of the fabric.

Web Consolidation:

Fiber Bonding: Controlled airflow contributes to the consolidation of the fiber web before bonding. This is essential for achieving a cohesive structure in the fabric.

Airlaid Process:

Fiber Placement: In the airlaid process, where fibers are blown onto a moving belt, airflow controls the placement and alignment of fibers. This is critical for achieving a consistent and controlled fiber distribution.

Web Formation:

Web Uniformity: Airflow plays a role in maintaining the uniformity of the web, ensuring that fibers are evenly spread and aligned before subsequent manufacturing steps.

Delamination:

Definition:

Layer Separation: Delamination refers to the intentional or controlled separation of layers within the non-woven fabric. This process involves splitting or separating the layers to achieve specific characteristics.

Embossing Process:

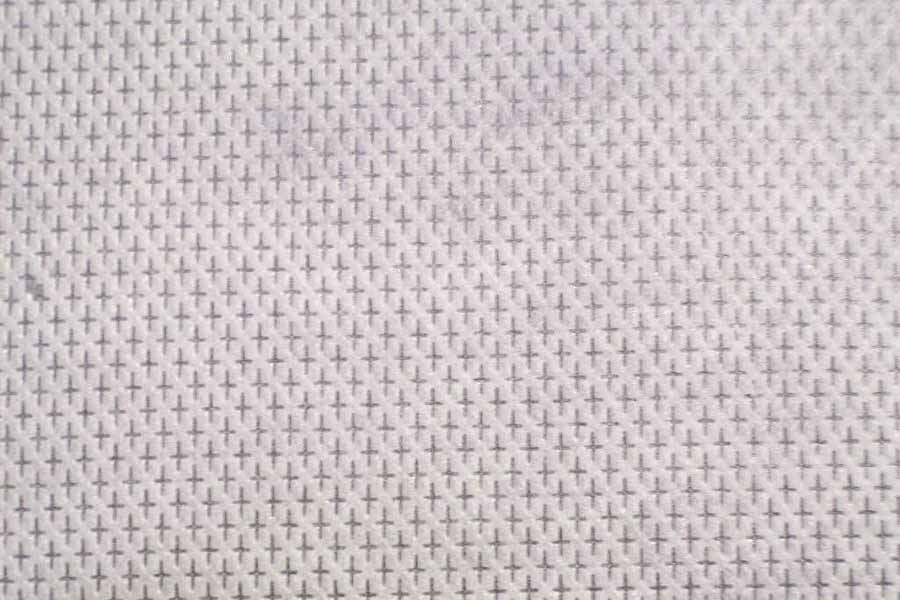

Texturing: Delamination is often employed during the embossing process to create textured patterns on the fabric. It involves separating layers of the fabric to achieve a three-dimensional surface.

Pattern Formation:

Embossed Designs: Delamination allows for the creation of embossed designs by selectively separating layers in specific areas. This results in raised patterns and textured surfaces on the fabric.

Texture Control:

Controlling Thickness: Delamination is used to control the thickness of certain areas in the fabric, influencing the overall texture and feel. It provides a way to achieve variation in thickness for aesthetic or functional purposes.

Improved Breathability:

Enhancing Breathability: Delamination can be utilized to enhance the breathability of the fabric by creating channels or gaps between layers. This is important in applications where airflow and moisture management are critical.