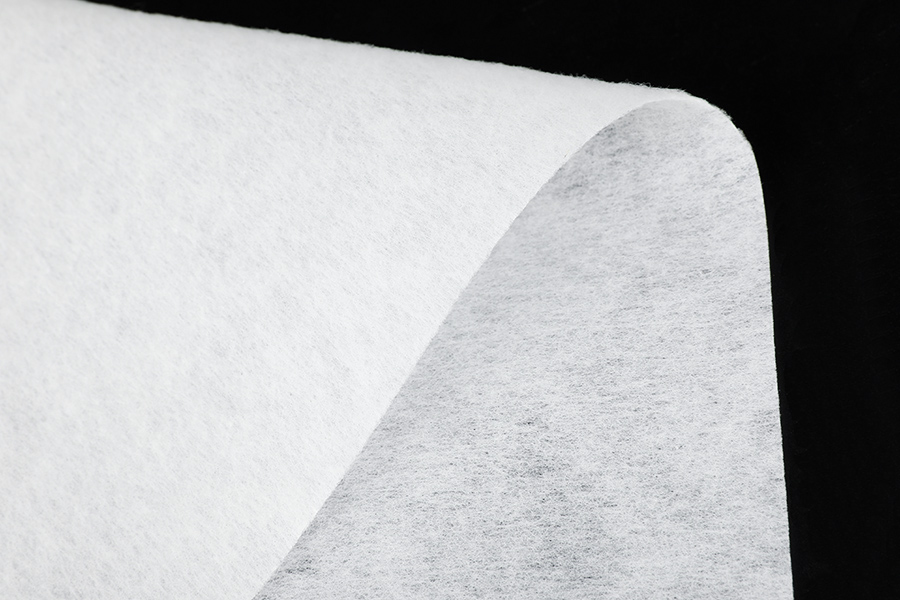

The cooling process is critical to stabilizing fabrics, particularly in the context of hot air bonding used in

Hot Air Non-woven Fabric production. This step is essential for several reasons:

Solidification of Bonds: During the hot air bonding process, the synthetic fibers are heated and softened, causing them to partially melt and bond together at their contact points. Without proper cooling, the fibers would remain in a semi-melted state, leading to weak or unstable bonds. Cooling allows the melted fibers to solidify, ensuring that the fabric maintains its structural integrity and strength.

Prevents Stickiness: In the hot air bonding process, the fabric comes into contact with heated elements or machinery. If the fabric is not cooled adequately, it may stick to the equipment, causing handling difficulties and potential damage to the fabric during further processing or cutting.

Reduces Shrinkage: Cooling helps to set the fibers in their bonded state. Properly cooled fibers are less likely to shrink or deform during subsequent handling or exposure to heat, ensuring dimensional stability in the final fabric.

Enhances Handling: Cooled fabrics are easier to handle and process. They become less pliable, making cutting, shaping, and folding more manageable during subsequent manufacturing stages.

Improves Efficiency: Effective cooling allows the fabric to move through the production line more efficiently. Faster cooling times can increase production throughput and reduce the overall production time.

Ensures Uniformity: Cooling the fabric uniformly helps to maintain consistent bonding throughout the entire material. This uniformity is crucial for achieving predictable and reliable performance in the final product.

Quality Control: The cooling process provides an opportunity for quality control inspection. Manufacturers can assess the fabric's appearance, strength, and other characteristics during cooling to identify any defects or issues that may have occurred during the bonding stage.

The cooling process in hot air non-woven fabric production is an essential step that ensures the fabric's stability and quality. Proper cooling contributes to the fabric's overall performance and suitability for its intended applications in various industries. It allows the fabric to retain its bonded structure, resist deformation, and meet the required specifications, making it a reliable and valuable material for numerous end uses.